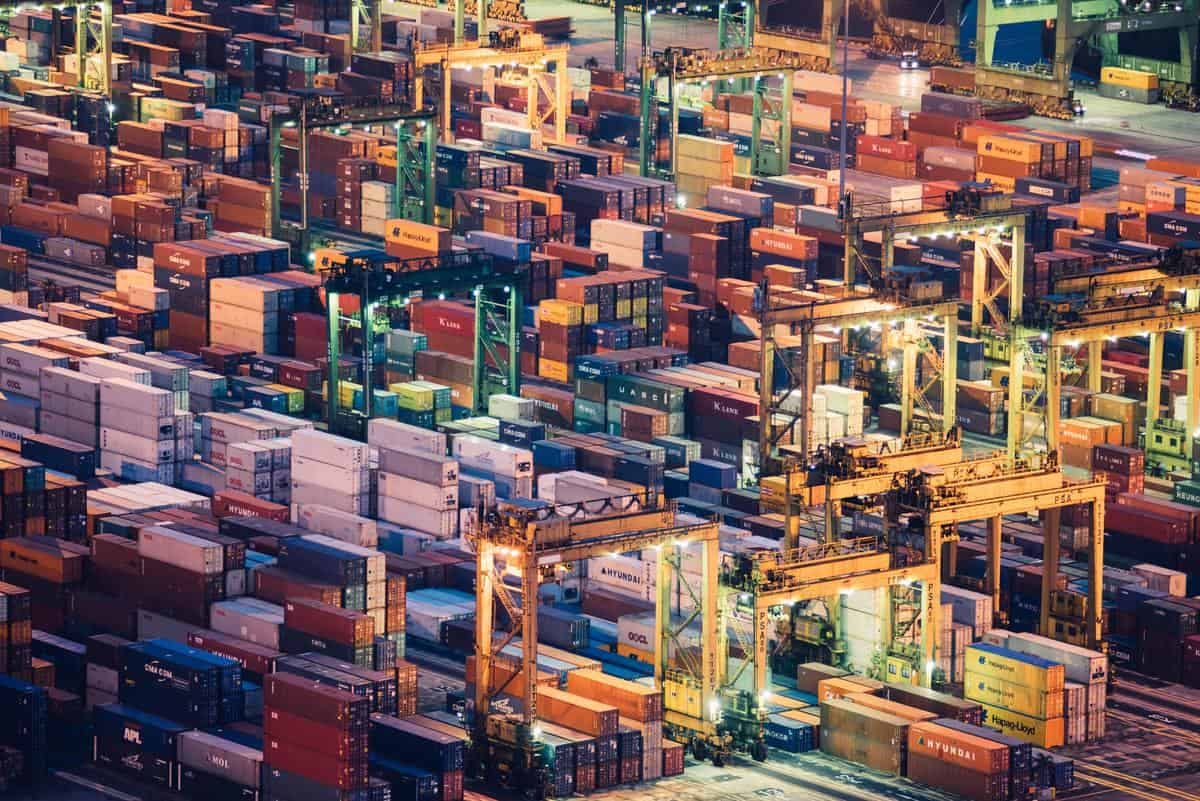

An ongoing container glut at the Port of Long Beach and Port of L.A., California, highlights the danger of supply bottlenecks. Ports in the United States are reportedly growing more congested by the day in a vicious cycle that is grinding supply chains to a halt.

Port bottlenecks

The Port of Long Beach and the Port of L.A. are the largest container terminals in America and are responsible for handling the majority of imports arriving from Asia. According to CNN, “Virtually every U.S. home contains items that came through the ports of Los Angeles or Long Beach.”

The bottleneck has been caused by a surge in American demand for consumer goods. According to Container Trades Statistics, 25 per cent more cargo was shipped from Asia to the U.S. in the first eight months of 2021 compared with the same period in 2019 pre-pandemic.

The problem has been exacerbated by the pandemic, labour shortages, and existing supply chain infrastructure issues.

The Mayor of Long Beach, California, said, “We are facing an unprecedented cargo surge at the ports of Long Beach and Los Angeles due to major global pandemic production shifts and decades-old supply chain challenges.”

Before the crisis, when a ship arrived at the Port of Long Beach, it went straight to berths to offload containers and get new ones loaded back in their place.

The process at a functioning port looks something like this:

- A ship arrives at the port

- Goods are unloaded from containers

- Awaiting lorries are loaded with goods

- Empty containers are loaded back onto the ship

- Loaded lorries carry goods to distributors

The current situation at Long Beach looks like this:

- A ship arrives at the port

- Not enough staff are available to either unload containers or drive lorries

- Containers begin to stack up at the port

- Ships are diverted to other ports

- Waiting ships cause congestion at ports

- Supply chain slows

Negative feedback cycle

The situation was aptly described as a “negative feedback cycle” last month by Ryan Peterson, CEO of the freight logistics company Flexport.

Mr Peterson went to Twitter to share his experience of the congested port, detailing his observations on a three-hour boat tour of the overloaded complex in Long Beach, California.

In a lengthy Twitter thread, Mr Peterson noted that port operations at Long Beach were “at a standstill” and that “containers [were] piling up in the terminal yard” due to a lack of space.

Mr Peterson noted on Twitter: “It seems that everyone now agrees that the bottleneck is yard space at the container terminals.

“The terminals are simply overflowing with containers, which means they no longer have space to take in new containers either from ships or land. It’s a true traffic jam.”

Economic impact

The economic impacts of the backlog will have a wide-reaching effect on the American economy. These include:

- The glut has suspended supply chains, preventing retailers from stocking the goods eager to sell to holiday shoppers.

- U.S. factories awaiting parts have had to slow or stop production temporarily.

- Supply chain issues are a significant factor driving up prices for consumers, feeding into the worst inflation the U.S. has experienced in decades.

Mr Peterson called the situation “a negative feedback loop that is rapidly cycling out of control”, adding that “if it continues unabated [it] will destroy the global economy.”

“We don’t need to do the best ideas. We need to do ALL the ideas,” he said.

How the U.S. is tackling the issue

In response to the supply chain crisis, U.S. President Joe Biden has established a task force to relieve the bottlenecks.

The White House has granted permission for the Port of Long Beach and Port of L.A. to operate 24 hours a day to ease the bottleneck. The White House has also considered deploying the National Guard to assist with the labour shortage.

From yesterday, authorities were able to issue fines to companies whose containers are lingering at the Port of Long Beach or the Port of L.A.

The penalties are designed to encourage movement in the supply chain by adding extra incentives for companies to collect their goods.

Containers that are ready for truck transport will have nine days before a fine is issued. After that time, a $100 fine per container will be issued, with an additional $100 every day that each container remains at the port.

Mr Peterson wrote on Twitter, “Tomorrow (November 1) the new fees for not picking up your containers on time at the Ports of LA-Long Beach go into effect. The fees go up by $100 every day, so by Day 30 charges reach $46,500 per container.”

Locally, the City of Long Beach has allowed containers to be stacked twice as high as is typically allowed, up from two to four or five.

“It has recently come to the City’s attention the Municipal Code contains zoning provisions that limit the number and/or height of shipping container storage, that if relaxed for a short time could provide some assistance during this national crisis,” the City of Long Beach wrote in a statement.

How businesses can protect themselves from supply chain disruptions

As the globe’s largest economy, the U.S. is one of the world’s most important export markets. Companies exporting consumer goods and raw resources will face significant challenges in getting their products to U.S. shores.

In the coming months and years, businesses will have to navigate the financial and operational challenges of supply chain issues while still addressing the needs of their customers and suppliers.

Both exporters and importers have an excellent opportunity to use this crisis to create a more resilient supply chain for their business.

Forbes suggests the following five steps for businesses to protect themselves from supply chain disruptions:

1. Invest in the right technology

Technology investments are relatively cheap when compared to the lost sales caused by a lack of inventory.

2. Diversify suppliers and manufacturing partners

Hedge your bets—don’t rely on one supplier for a critical component of your product.

3. Incorporate risk management into your supply chain management

Develop a supply chain risk matrix that allows the assessment of probabilities of supply chain disruption, and use it to mitigate and monitor risks.

4. Create a procure-to-pay purchasing system

Move from manual, paper-based purchasing to lower-cost, higher-control automated purchasing that links all relevant functions across your business.

5. Focus on the basics—cash is king

Focus on how long it takes to convert inventory to cash. Implement practices to accelerate cash collection from customers.

Read more:How high growth e-commerce companies are navigating supply chain disruption

Read more: Warehousing wisdoms: strengthening the link between your supply chain and your CEO

Keep up to date with our stories on LinkedIn, Twitter, Facebook and Instagram.