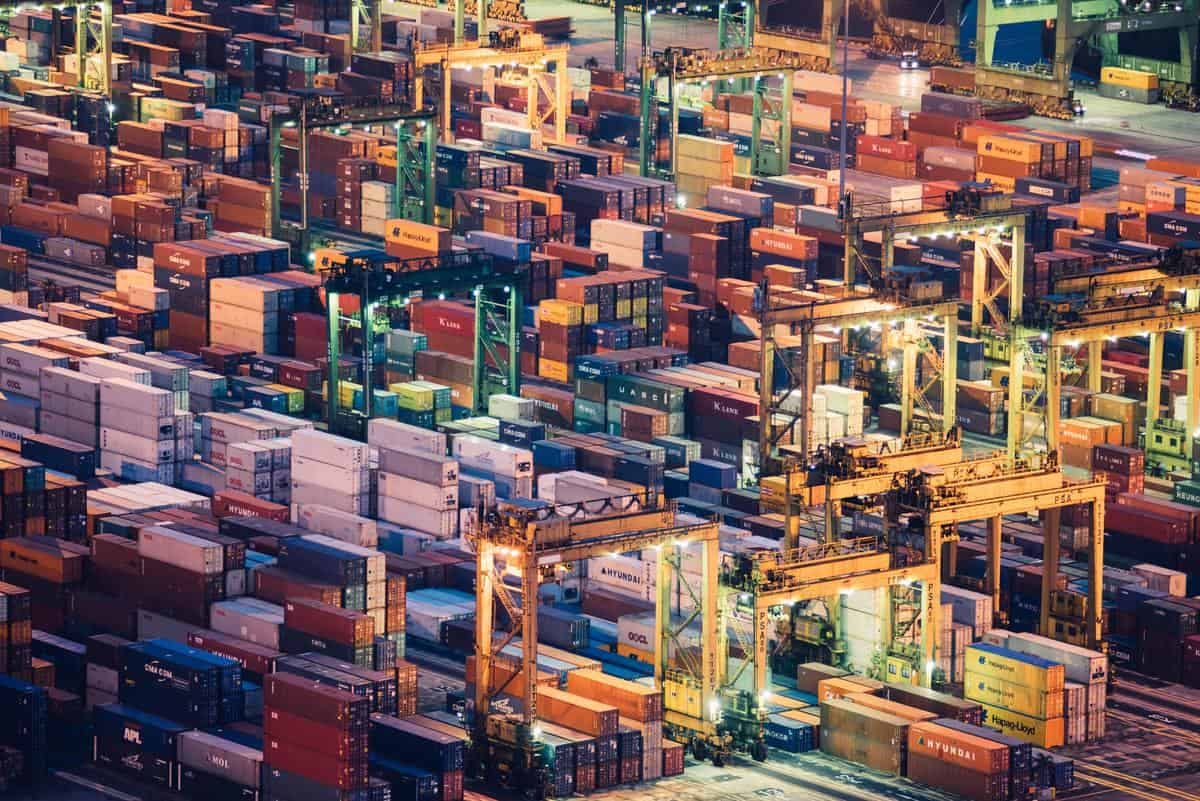

In the wake of the pandemic, supply chain issues have plagued much of the world, leading to delivery delays at all points in the chain. Today, national employer association Ai Group has released a report exploring recent business experiences of supply chain pressures.

What has caused the supply slowdown?

Global supply chains have been under pressure for some time now; the COVID-19 pandemic has only exacerbated existing issues. Demand for goods has reached an all-time high, leading to unprecedented levels of freight moving around the globe. Ai reports that rates on key global trade routes are around seven times higher than two years ago.

Ai Group Chief Executive Innes Willox said, “The COVID-19 pandemic has exposed deep weaknesses in the operations of global and domestic supply chains and laid bare many Australian vulnerabilities as an island nation with 98 per cent of trade and most jobs connected to or reliant on sea freight in some way.”

Rising freight charges, a lack of space on ships, and extra costs for priority loading, which still does not guarantee on-time delivery, is placing stress on Australian importers and exporters.

Mr Willox said, “Supply chain chaos has been created by a combination of factors including the increase in global demand for goods; lengthy lockdowns and infections of workers; a global shipping container shortage; reduction in shipping services and port skipping; Australian industrial action; and rising costs. This situation is projected to only moderately ease by 2023 and beyond.”

He says that global trade and diplomatic tensions are stoking the existing supply chain chokes.

“There is increasing concern about geostrategic tensions, trade conflicts and their associated unknowns. This creates real risks for businesses reliant on distant suppliers and generates an incentive to change the way they do business, and to avoid over-dependency on particular countries or regions (especially those where trade or diplomatic tensions exist),” said Mr Willox.

How have Australian businesses been impacted

The COVID-19 crisis has caused fundamental changes in consumer behaviour, supply chains, and channels to market and is knocking businesses off balance.

Shipping disarray is impacting the ability of many businesses to meet contractual obligations or the expectations of their customers. Some are being pushed out of the market altogether due to eroding profits and delivering on time.

The survey reports that up to 65 per cent of businesses reported having increasing trouble sourcing their standard inputs. Ai says that just over half of Australian companies expect their ability to source inputs would continue to be disrupted in 2022.

Mr Willox said, “27 per cent of businesses expected no change to their ability to source inputs in 2022 compared to 2021, but it is unclear whether this is a cause for optimism or indication businesses are expecting the same problems and pressures to continue.”

The ACCC has reported that delayed shipments and rapidly rising freight rates put intense pressure on Australian exporters and importers. The Retailers Association has warned ‘it’s the season to shop early’ over Christmas 2021 stock availability concerns. The construction industry has also been hit with supply chain problems causing delays.

“Supply chain problems should be assessed by how essential the goods are to the wellbeing of Australians and how critical they are to the production of an essential good or service whether for domestic consumption or for export.

“These pressures can undermine our economic recovery from the pandemic and ultimately dampen economic growth,” Mr Willox said.

What can be done

Australian businesses have adopted successful strategies to strengthen their supply against global shocks. While strategic management comes at a cost, understanding options will be vital if supply chains remain strained in 2022.

Mr Willox said, “While we may not be able to control the global factors negatively impacting supply chains, we should not shy away from looking inward and improving our own domestic performance and efficiencies.”

The Ai report reveals the strategies businesses are using, they include:

- Absorbing costs and building up inventories

28 per cent of respondents indicated that building up inventories was their number one plan to ensure inputs are available and in stock when needed to improve the reliability and resilience of their supply chain.

- Finding local suppliers

Finding local supply is a great option when possible and/or practical. One surveyed member reported that their sales had been trending up for a ‘while,’ primarily due to customers looking to buy local for certainty in the supply chain by reducing reliance on overseas suppliers.

- Innovation

Innovation, automation, and new technologies are not only helpful in relieving supply chain pressures when applied to generating better efficiencies on our ports, logistics systems and their supporting infrastructure; they’re also useful in growing local industry.

- Offshoring and nearshoring

Although moving offshore is often seen as a loss for Australia or as an undesirable solution, it may be positive in some cases. As discussed above, if an Australian business moves only part of its operations offshore, it becomes a multinational. It may unlock the ability to scale far greater heights by leveraging all locations’ competitive advantages.

Global supply chains are drawing more attention than in previous years on a policy level. These issues have direct implications for many policy areas. Supply chains can easily undermine government funding initiatives, economic stimulus and targets.

“The recently announced Productivity Commission inquiry into Australia’s Maritime Logistics System is a positive development that will further identify the impacts that go beyond the productivity on our wharves, the reliability of our supply chains and the high prices faced by businesses and households.

“Hopefully, determined actions will follow the report’s recommendations next year,” Mr Willox said.

Read more:Everything old is new again: Scott McCorkell’s marketing predictions for 2022