Australia’s first hardware incubator launches in Brisbane, next week, with the entrepreneur at its helm promising resource-intensive startups efficient and affordable access to equipment that will streamline the development and commercialisation of ground-breaking products.

Arc Hardware Incubator is being delivered by Vektor Innovation whose CEO, Victor Vicario, told Dynamic Business that early-stage hardware ventures can get derailed at the outset due to expenses incurred during the prototyping stage.

“When a hardware innovator is prototyping a physical product, they tend to require machinery that, off the bat, can cost tens of thousands of dollars,” he said. “Plus, the machines an innovator will require generally have a specialised function, meaning they’ll get limited use out of them relative to the cost.

“Unlike a software startup, which can do all their product development from a laptop, hardware startups don’t have the luxury of a single piece of equipment that allows them to develop their prototype. On top of that, there’s a bit of a Catch 22 scenario where hardware innovators require capital to develop their prototype… but investors want to see a prototype before they give them money.”

In-house experts, equipment

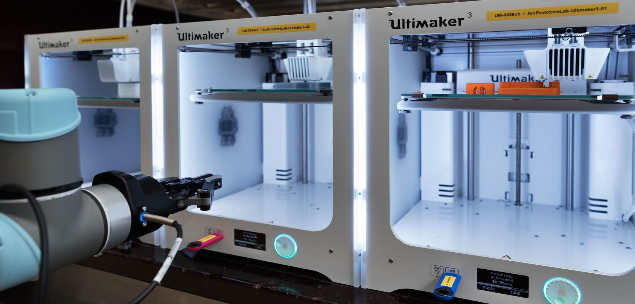

Vicario said Arc, which is 460 m² facility in Fortitude Valley, addresses these difficulties for its members by providing them with flexible access to a range of cutting-edge advanced prototyping and manufacturing equipment that might otherwise be beyond their means. Resources include computer labs with pre-installed industrial design software, 3D printers (“stay tuned for carbon fibre 3D printing”), laser cutters, CNC machines and soldering stations as well as assembly and testing facilities.

In addition, Vicario said Arc has a ‘media lab’, where members can access audio and video equipment to produce content for “use in marketing, crowdfunding campaigns or investment pitches”.

According to Vicario, providing members with access to in-house technical and business expertise as well as ongoing mentoring and opportunities for industry networking and investor engagement has been “as important as ensuring they have the right prototyping and manufacturing resources”.

To cater for hardware startups at different stages of their journey – from pre-revenue ventures still finalising their core talent through to more established companies – Vicario said Arc operates a subscription-based model, with “access to prototyping and manufacturing technologies from as little as $25 per day”.

Remote access for members

Leveraging a $260,000 Incubator Support grant from the Federal Government, Vicario said Arc will very shortly beginning rolling out a series of programs designed to engage the hardware startup community.

“We have startup weekends planned as well as industry-specific hackathons where innovators will address real-world problems,” he said. “We’ll also introduce a pre-accelerator program to assist innovators with early-stage product development and a post-accelerator program to prepare companies for the logistical issues and regulatory requirements associated with manufacturing in large volumes.

Vicario said Arc is able to accommodate between 30 and 40 startup teams due to the fact that it houses equipment that can be operated remotely.

“Nearly all of our equipment can operate for a long period of time – ten, twenty, thirty hours or more – so we can create benefits for a lot of teams even when they’re not physically present at the incubator,” he said. “They can send jobs remotely and monitor when they can come into the incubator and what’s equipment has been booked. It’s an efficient approach that allows us to coordinate those numbers.

“Incredibly varied membership”

Although Arc doesn’t officially open its doors until Wednesday, 21 February, Vicario said he and his team have been accommodating ‘beta’ tenants since November 2017.

One tenant making use of the incubator space is developing a wearable device that draws on data collection, senor technology and an alert system to address the safety risk of mine truck drivers falling asleep behind the wheel.

Another tenant has developed a handheld device that uses sensors to empower people with vision impairments to navigate three-dimensional objects in the real-world.

A third is working on a manufacturing machine, with a view to enabling small businesses to compete in the advanced manufacturing space.

“Other tenants are working in robotics, education, drone-tech, battery tech including soft-charging and so on,” Vicario commented. “Already, our membership is incredibly varied.”