Tell that to the 3D printing industry.

In the 20th century, the Australian manufacturing industry boomed. Great Aussie brands made their products locally, creating jobs and wealth alike.

These days, few would say the current state of the industry is in good health. Just last month the announcement by Ford that manufacturing their vehicles in Australia was no longer viable, was seen by many as yet another nail in the coffin of the industry.

And it was, at least, for those playing under the old rules.

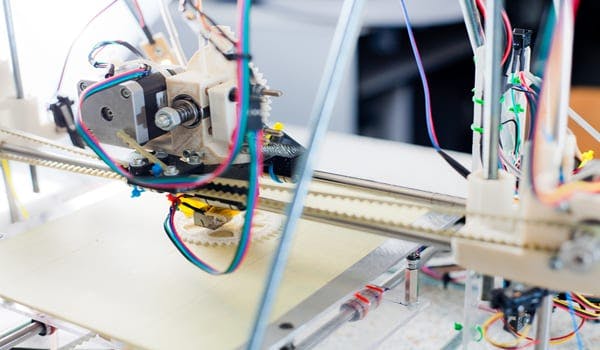

For those businesses willing to innovate – willing to do things a little differently – 3D printing represents an undeniable opportunity.

Australian metal products manufacturer Williams United, a company founded in 1948, is one such business.

Producing customised sheet metal products for some 65 years, managing director Dean Williams, the grandson of its founder, said he wasn’t willing to stand by and watch his family business become another manufacturing casualty.

“We wanted to diversify the range of services that we offer, because we worry about only relying on the traditional manufacturing methods. So we thought, let’s get into 3D printing, and we called it Williams 3D,” Williams said.

Launched in July this year, the 3D printing sector of the business is Williams’s investment in future-proofing his business. He believes 3D printing is the next industrial revolution, and has the potential to completely change the face of manufacturing.

“I really think we need to adapt in this country, because there just literally isn’t the market for manufacturing anymore, and we’re so far away from the rest of the world, so there’s the cost of transportation – but 3D printing works so well for Australia,” Williams said.

Utilising 3D printing means highly complex prototypes can now be designed and printed in a matter of hours, small quantities can be produced cheaply and easily and potential design flaws can be eliminated early on. “That all adds up to considerable time and cost savings for businesses,” Williams added.

And that’s the rub – 3D printing means that a business can make two different items for the same price as two identical items, and complexity can be built in for free.

“This is something that we’ve never seen before. Traditionally you would have to make thousands of the same item in order to reduce the cost, whereas that’s all turned on its head now,” Williams said.

The US are leading the charge in the 3D printing industry, and businesses such as Shapeways saw the potential in the consumer market earlier on. “I think that’s where the future of manufacturing has to be for Australia. Because we don’t have the population for mass production, and because it’s not particularly labour intensive, so with Australian wages being so high, 3D printing reduces the amount of direct labour that goes into manufacturing an item,” Williams said.

Williams believes the technology has the ability to essentially level the playing field from a cost point of view.

“As a nation we’re quite creative, and we have many industrial designers here who are designing great products, but typically they’re going over to China to have it manufactured. With 3D printing, we can keep a lot more of the production and manufacturing in Australia,” he said.